Khase ea tšepe ea khabone e loketseng tee

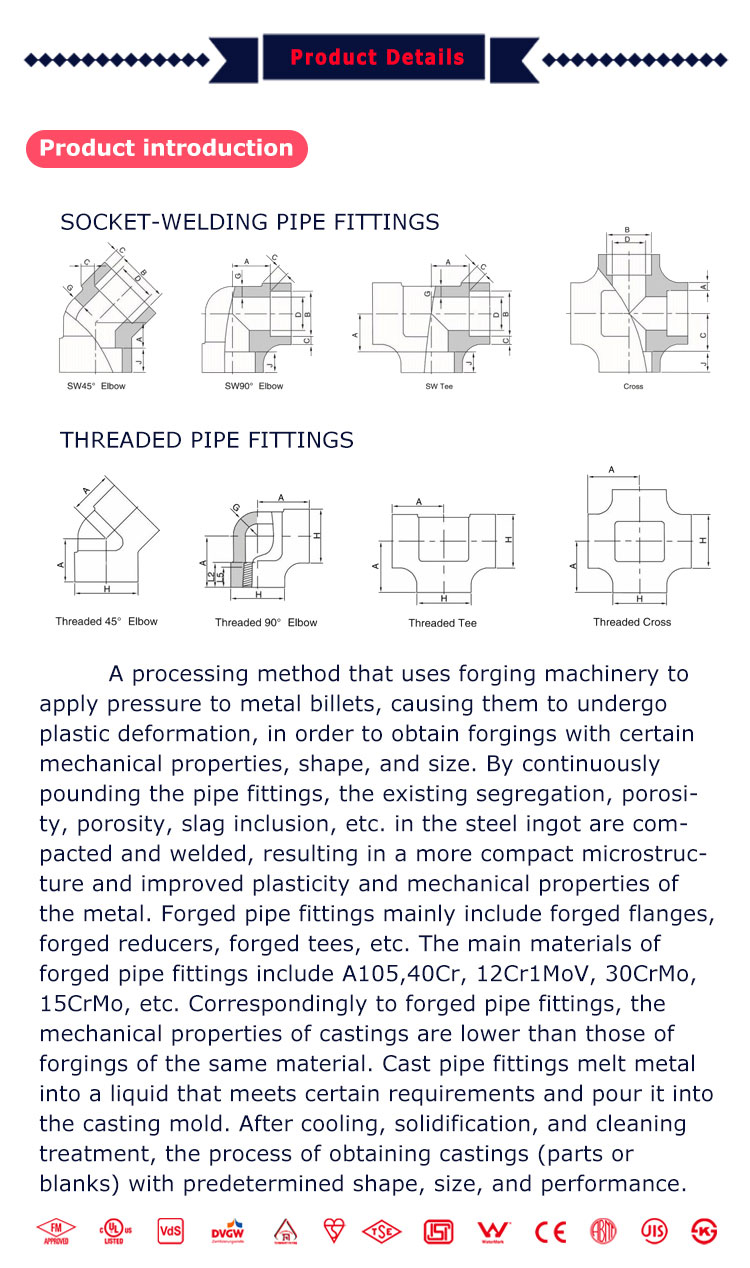

Mokhoa o sebetsang o sebelisang mochini oa ho sebetsana le mechini ho sebetsana le mathata a tšepe, e ba etsa hore ba tšoarele ka lebaka la ho tšoarela, e le hore ba tšoarele ka thepa ena, sebopeho, le boholo.

Ka ho nnehanya ho ntša lipampiri tsa phala, ho na le tshetsi, bofokoli, bosetsi, boea ba lets'ollo la tšepe le thepa e ntlafalitsoeng ea metlae.

Li-cupe tse felisitsoeng haholo-holo li kenyelletsa ho fanoa ka likhatello tse halikiloeng tse nang le liqoso, tse thellisang metso, jj.

Lisebelisoa tse ka sehloohong tsa li-cipe tse kholo li kenyelletsa a105,40cr, ea bohlano, ea bohlano, ea 15crmo, jj.

Ka mokhoa o ts'oanang le ho fanoa lijo-pele tsa phala, thepa ea mechini ea ho lelekoa ha e tlase ho feta ea ho phomola ka thepa e le 'ngoe.

Li-phala li qhala tšepe li qhibilisetse metsi a lekanang le metsi a kopanang le litlhoko tse itseng ebe o tšela ka hlobo e tšelang. Kamora ho pholile, 'nete, le kalafo ea ho hloekisa, ts'ebetso ea ho fumana litlolo (likarolo kapa likheo) ka sebopeho se reriloeng esale pele, boholo le ts'ebetso.